Custom Gunstock

This article shows what goes into fitting a custom gunstock. The top picture shows a custom stock that I got directly from "Richards Micro-fit". It's a spectacular piece of "A" Grade walnut that came 96% inletted. I'm using it to build a great looking a left handed .270 Ruger M77 Mark II rifle for a good friend. The next time he has a long wait in his deer stand, he'll have a pretty cool rifle to look at. This article shows the progress, and it explains the steps required to complete this project.

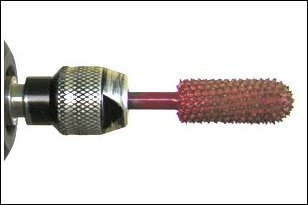

One of the best tools I've found for removing excess wood and

shaping a stock, is to use a Dremel Tool using a special burr like this

one. Any burr of this type will to the job quickly, and with good control.

Fitting and finishing a custom gunstock takes a lot of

time, but it's always worth it. I've done similar stocks before,

and every one has turned our real well. However, I'm definitely

not the fastest craftsman around. It took me 13 hours to get it

this far. The barreled action now slips into this stock, and

it's a perfect fit. Most of the hard work is done, but this

stock still has a long way to go. The next step is to block sand

the flat surfaces perfectly flat, and make the edges straight and crisp.

If you would like to see "more" information about this project . . . .